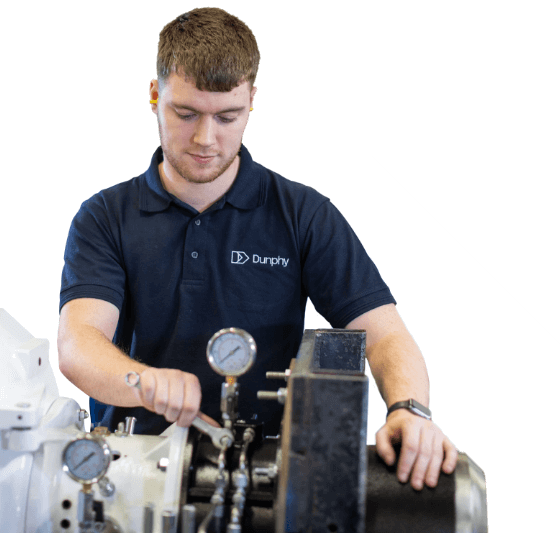

Statutory Non-Destructive Test Inspections

Steam boilers are legally required to be examined by a Competent Person (CP) per a Written Scheme of Examination (WSE). Typically, this requires an annual inspection and working examinations. A Non-Destructive Test (NDT) must be carried out every 5 years. Dunphy can prepare any boiler to ensure it meets the expectations for these assessments, so you’re in the optimum position to pass regulations.