What is involved in manufacturing a skid mounted plantroom?

We work closely with our clients to ensure that all aspects of the project are considered, and that the final product meets all of their requirements and is completed on schedule. Achieving this requires a dedicated team at each stage of the design and build and throughout the process you will have access to our expert staff as they support you through the design, construction, installation, testing and inspection processes.

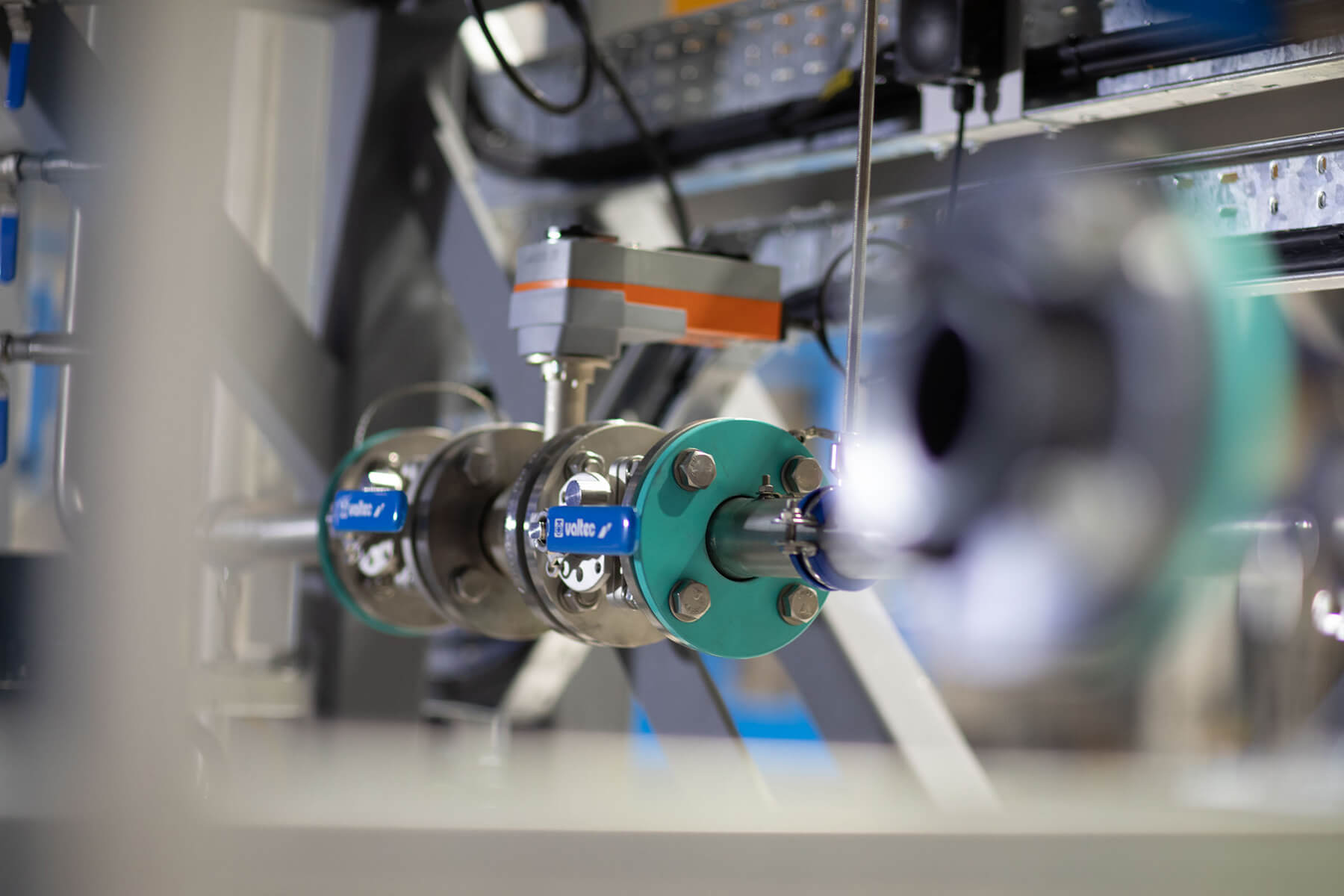

Dunphy designs and manufactures all the key energy centre components in-house, including axial air flow burners, sequencing control systems, BG01 control panels, hotwells, gas boosters and fuel pumps.

We prepare all FDS reports, DSEAR analyses and SIL assessments.

Once delivered to site, the energy centre is rapidly reconnected and then commissioned by our team of experienced mechanical and electrical engineers.

Why choose a skid mounted plantroom?

- Speed. Site work can continue whilst we are building the plantroom, at which point it can then be transported to site and rapidly installed.

- Safety. We are ISO 45001 accredited and SafeContractor approved with a keen focus on health and safety.

- Reduce your onsite safety risks by offsetting a significant part of your project to us.

- Quality. We believe in providing a high-end product that will stand the test of time.